Packaging 101: The Complete Guide

- Packaging 101

- Types of Packaging

- Aseptic Packaging

- Blister Packaging

- Biodegradable Packaging

- Bulk Packaging

- Carbon Neutral Packaging

- Circular Packaging

- Clamshell Packaging

- Compostable Packaging

- Cornstarch Packaging

- Corrugated Packaging

- Discreet Packaging

- Ecommerce Packaging

- Flexible Packaging

- Frustration Free Packaging

- Retail Packaging

- Secondary Packaging

- Smart Packaging

- Sustainable Packaging

- What is a PR Package?

- What is a Poly Mailer?

- Packaging Design Ideas

- AI Packaging Design

- Bakery Packaging Ideas

- Bath Bomb Packaging Ideas

- Bath Salt Packaging Ideas

- Body Butter Packaging Ideas

- Body Oil Packaging Ideas

- Body Scrub Packaging Ideas

- Brownie Packaging Ideas

- Cake Packaging Ideas

- Cake Pop Packaging Ideas

- Candle Packaging Ideas

- Candy Packaging Ideas

- Canva Packaging Design

- Chocolate Packaging Ideas

- Cinnamon Roll Packaging Ideas

- Clothing Packaging Ideas

- Coaster Packaging Ideas

- Coffee Bag Design Ideas

- Cookie Packaging Ideas

- Cosmetics Packaging Design

- Cotton Candy Packaging Ideas

- Cupcake Packaging Ideas

- DIY Packaging Ideas

- Dog Treat Packaging Ideas

- Food Packaging Ideas

- Empanada Packaging Ideas

- Etsy Packaging Ideas

- French Fries Packaging Ideas

- Frozen Food Packaging Ideas

- Hair Extension Packaging Ideas

- Handbag Packaging Ideas

- Jewelry Packaging Ideas

- Keychain Packaging Ideas

- Lash Packaging Ideas

- Lip Gloss Packaging Ideas

- Macaron Packaging Ideas

- Minimalist Packaging Ideas

- Mug Packaging Ideas

- New Employee Welcome Kit Ideas

- Packaging Colors

- Packaging Inserts Ideas

- Packaging Logo Design

- Packaging Typography

- Perfume Box Design Ideas

- Pizza Box Design Ideas

- Popcorn Packaging Ideas

- Scarf Packaging Ideas

- Skincare Packaging Design Ideas

- Soap Packaging Ideas

- Sock Packaging Ideas

- Sticker Packaging Ideas

- Sunglass Packaging Ideas

- Sustainable Packaging Ideas

- Tea Packaging Ideas

- Wax Melt Packaging Ideas

- Weed Packaging Ideas

- T-Shirt Packaging Ideas

- Wine Packaging Design Ideas

- What is a Packaging Engineer?

- Types of Packaging Materials

- Chipboard vs Cardboard

- Compostable Packaging Materials

- Alternatives to Plastic Packaging

- Edible Packaging Materials

- Food Packaging Materials

- Are Poly Mailers Recyclable?

- How to Recycle Cardboard Boxes

- How to Recycle Packaging Materials

- Medical Device Packaging Materials

- Mono Material Packaging

- Pharmaceutical Packaging Materials

- Plastic Food Packaging

- Protective Packaging Materials

- Reusing Packaging Materials

- Types of Packaging Foam

- Void Fill Packaging

- What is Chipboard?

- What is Kraft Paper?

- Offset vs Digital Printing

- RGB vs CMYK Printing

- Screen Printing vs Digital Printing

- Screen Printing vs Sublimation

- What is a Dieline in Packaging?

- What is Die Cutting?

- What is Digital Printing?

- What is Flexographic Printing?

- What is Glassine Paper?

- What is Offset Printing?

- What is Spot UV Printing?

- Why is 300 DPI Good for Printing?

- How to Estimate Shipping Costs

- How to Pack Glass for Shipping

- How to Mail a Bubble Mailer

- How to Make a Shipping Label

- How To Measure Box Dimensions and Sizes

- How to Ship Alcohol

- How to Ship Artwork

- How to Ship Books

- How to Ship a Cake

- How to Ship Candles

- How to Ship Clothes

- How to Ship Cookies

- How to Ship Food

- How to Ship a Laptop

- How to Ship a PC

- How to Ship Plants

- How to Ship Shoes

- How to Ship Vinyl Records

- Packaging Symbols

- Shipping Large Items

- What is a Delivery Exception?

- What is Shipping Insurance?

Discover Phillip Akhzar’s journey, the Founder and CEO of Arka, bringing 16 years of expertise in packaging and supply chain logistics. Read more on Arka.

Importance of Packaging Materials in Pharmaceuticals

Pharmaceutical packaging materials are pivotal guardians of medicine safety and efficacy. Beyond their aesthetic allure, these materials serve many roles, from fortifying medicines against external threats to ensuring adherence to rigorous regulatory benchmarks.

• Protecting Medicines from External Factors: Foremost among the duties of pharmaceutical packaging materials is to shield medicines from external elements that could compromise their integrity. Exposure to light, moisture, and air has the potential to degrade the potency of drugs. Ingeniously crafted packaging acts as an impermeable barrier, preserving the pharmaceutical composition and prolonging the medication's shelf life.

• Enhancing Product Safety: The role of drug packaging materials extends beyond mere containment; they actively enhance product safety. Sturdy packaging thwarts contamination, guaranteeing that the medicine reaches the end-user in the same pristine condition as when it left the manufacturing facility. This is particularly crucial in averting microbial contamination, a threat that could imperil patient safety.

• Compliance with Regulatory Standards: Operating within stringent regulatory frameworks, the pharmaceutical industry upholds standards set by organizations such as the United States Pharmacopeia (USP), the European Pharmacopoeia (Ph. Eur.), and the International Organization for Standardization (ISO).

The United States Pharmacopeia (USP) dictates drug quality, purity, strength, and consistency standards. Pharmaceutical packaging materials must align with these standards to ensure the integrity of the enclosed medication. Similarly, adherence to the European Pharmacopoeia (Ph. Eur.) ensures compatibility with European regulatory requirements, facilitating the global distribution of pharmaceuticals.

Furthermore, the International Organization for Standardization (ISO) delineates international standards for diverse industries, including pharmaceuticals. Packaging materials that meet ISO specifications ensure product quality and streamline international trade by providing a common language for manufacturers, regulators, and consumers.

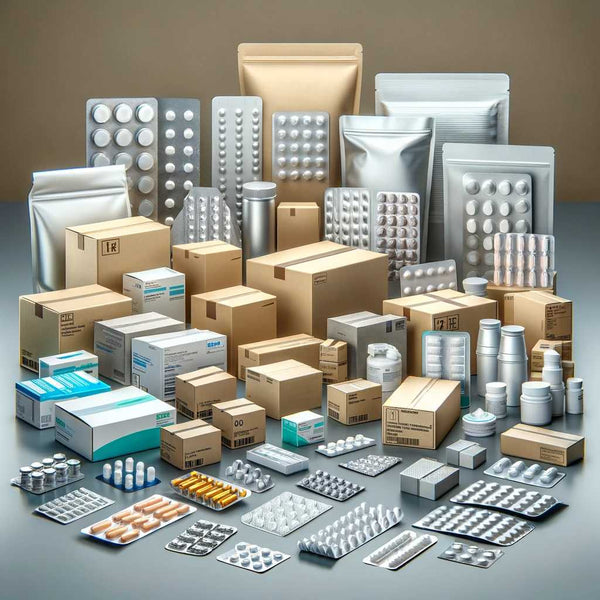

Types of Pharmaceutical Packaging Materials

The selection of pharmaceutical packaging materials is a pivotal choice for pharmaceutical companies, involving meticulous considerations such as safeguarding against external influences, ensuring stability, and prioritizing patient safety. Let's explore diverse packaging materials, ranging from primary to tertiary.

Primary Materials for Pharmaceutical Packaging

• Glass: Glass, a timeless option, is preferred for pharmaceutical packaging. It includes variations like Amber glass for light-sensitive medications and Clear glass for others. Classified into Type I, II, and III, glass is utilized to create glass vials, ampoules, and bottles, forming a dependable barrier against contaminants.

• Plastic: Plastic brings versatility to pharmaceutical packaging. High-Density Polyethylene (HDPE), Low-Density Polyethylene (LDPE), Polyethylene Terephthalate (PET), and Polypropylene (PP) are common plastic types employed. Molded into bottles, blister packs, sachets, and prefilled syringes, plastic materials blend functionality with convenience.

• Metal: Metal, encompassing Tinplate, Stainless Steel, and Aluminum, is chosen for its robust nature. These materials are integral in the production of containers, providing resilience against environmental factors and preserving product stability.

• Child-resistant and Sterile Packaging: Emphasizing patient safety, specialized designs and materials contribute to child-resistant and sterile packaging. These additional layers of protection ensure pharmaceuticals remain secure from unintended access or contamination.

Secondary Packaging Materials for Pharmaceuticals

• Paper and Cardboard: Secondary packaging often involves paper and cardboard, forming cartons and boxes. These materials contribute to the presentation of drug packaging and offer a dependable and sustainable option. At Arka, we offer eco-friendly custom shipping boxes that enhance product safety.

• Labels and Inserts: Information is paramount in pharmaceuticals, and labels and packaging inserts serve this purpose. These materials convey dosage instructions, warnings, and other essential details to end-users.

• Tamper-Evident Packaging: Tamper-evident packaging, encompassing seals, shrink bands, custom stickers and tape seals, is critical for maintaining the integrity of pharmaceutical products. It provides visible evidence of any interference, assuring consumers of the untouched state of the product.

• Blister Cards, Folding Cartons, Pouches, and Bags: Enhancing user experience, these materials offer convenient and organized packaging solutions. Blister cards, folding cartons, pouches, and bags provide flexibility in design and function.

Tertiary Packaging Materials for Pharmaceuticals

• Corrugated Boxes: Tertiary packaging, tailored for bulk shipment, often involves sturdy corrugated boxes. These boxes protect pharmaceuticals during transit, ensuring they reach their destination in optimal condition.

• Pallets: Pallets play a crucial role in pharmaceutical logistics, facilitating efficient storage and transportation in larger quantities.

• Shrink Wrap and Security Seals: Shrink wrap adds an extra layer of protection to tertiary packaging, ensuring stability during transportation. Security seals offer visible evidence of any tampering during transit.

3 Factors to Consider for Choosing Pharmaceutical Packaging Materials

Opting for the appropriate pharmaceutical packaging materials is a pivotal decision, wielding influence over a product's safety, effectiveness, and economic viability. When scrutinizing options, a judicious evaluation of three pivotal factors becomes imperative: adherence to safety and compliance standards, preservation of medicinal attributes, and the pursuit of cost-effectiveness.

Safety and Compliance

Degree of Shielding Required for the Product: materials must serve as a robust shield in pharmaceutical packaging, ensuring the preservation of enclosed drugs. The protection depends on the medication's sensitivity to external elements like light, moisture and air. Opting for materials adhering to stringent safety standards is paramount to maintaining the drug's potency.

Sterilization Compatibility: Preserving sterility is paramount. The chosen materials should align seamlessly with manufacturing sterilization techniques, ensuring the end product is devoid of contaminants. This dual assurance of regulatory compliance and patient safety is pivotal.

Preservation of Medicinal Properties

Impact of Dosage Form on Packaging: The dosage form significantly dictates packaging needs; Tailoring materials to powders, liquids or solid dosage forms minimizes degradation risks and upholds medicinal stability throughout the product's shelf life.

User-Friendly Convenience: Harmonizing preservation with user-friendliness is crucial; Packaging should not only shield the drug but also facilitate easy administration. Considerations like portability, resealability, and clear dosage instructions enhance the user experience, promoting adherence to prescribed regimens.

Cost-Efficiency

Optimizing the Filling Process: Efficiency in the filling process directly impacts production costs. Ensuring compatibility between pharmaceutical packaging materials and the chosen filling method streamlines operations, minimizing wastage and contributing to cost-effectiveness.

Balancing Quality with Cost: a comprehensive assessment of the cost of chosen packaging materials is essential while upholding quality standards. Factors such as material costs, transportation expenses, and storage requirements must be weighed against the benefits offered. Striking the delicate balance between quality and cost is imperative for the economic viability of pharmaceutical products.

Key Applications of Pharmaceutical Packaging Materials

From shielding prescription medications against environmental threats to preserving the sterility of dental products, pharmaceutical packaging materials play a pivotal role in safeguarding a spectrum of medical essentials.

Let's unravel the intricate applications of these materials, understanding how they act as custodians for prescription medications, dental products, biopharmaceuticals, and vaccines.

1. Prescription Medications: At the forefront of defending prescription medications, pharmaceutical packaging materials are a robust barrier from manufacturing to patient use. They shield medications from external adversaries like light, moisture, and air, preserving their stability and efficacy. Not only do these materials prevent contamination and tampering, but they also ensure patients receive the precise dosage prescribed by healthcare providers. Whether it's blister packs or vials, the meticulous choice of drug packaging materials is indispensable in maintaining the therapeutic potential of prescription medications.

2. Dental Products: In the realm of dental products, encompassing orthodontic devices, adhesives, and sterilized instruments, pharmaceutical packaging materials serve a dual purpose. Beyond shielding these products from environmental influences that could alter their composition, these materials guarantee they reach dental professionals in a state of pristine sterility. The demanding standards of dental hygiene necessitate packaging materials that are durable and adept at preserving the enclosed items' sterility until they are ready for use.

3. Biopharmaceuticals: The distinctive attributes of biopharmaceuticals, comprising proteins and antibodies, mandate using specialized drug packaging materials. These materials must establish a protective barrier against degradation from temperature fluctuations and light exposure. Furthermore, they must facilitate these delicate biological products' safe and efficient storage and transportation. By deploying state-of-the-art pharmaceutical packaging materials, the biopharmaceutical industry guarantees that these advanced therapeutic agents maintain their efficacy from production to patient administration.

4. Vaccines: The global dissemination of vaccines hinges crucially on pharmaceutical packaging materials to uphold their potency. Vaccines, particularly sensitive to temperature shifts, risk compromised efficacy if not stored and transported under optimal conditions. Packaging materials endowed with insulation and temperature-control features become imperative in preserving the cold chain integrity of vaccines. This meticulous approach ensures that these pivotal tools in disease prevention remain potent, whether destined for local clinics or the remote corners of the globe.

Final Thoughts

The world of materials used in pharmaceutical packaging is wide-ranging, offering diverse options customized for specific purposes. These materials are crucial in the pharmaceutical industry, contributing significantly to drug stability and addressing environmental concerns through recyclability.

As technology progresses and sustainability becomes more central, continuous exploration and innovation in pharmaceutical packaging materials are poised to influence the future landscape of drug delivery and healthcare practices.

Arka stands out as a guiding light in this terrain, delivering customized packaging solutions that cater to the varied requirements of the industry. Pledging to uphold standards of excellence and ingenuity, Arka transcends the role of a mere service provider; it evolves into a collaborator dedicated to guaranteeing that pharmaceutical products reach the final consumer in their best possible state.

FAQs on Pharmaceutical Packaging Materials

Are pharmaceutical packaging materials recyclable?

The recyclability of pharmaceutical packaging materials varies. Some are recyclable, while others may not be. Refer to packaging information or recycling guidelines for specific details.

How do pharmaceutical packaging materials impact drug stability?

Pharmaceutical packaging materials significantly influence the stability of drugs. These materials safeguard medications from external elements such as light, moisture, and air, which could otherwise compromise their effectiveness.